Al-Kawthar Tank Factory uses polyethylene material from SABIC, a Saudi company, which is approved for drinking water applications and is safe for use in compliance with the Saudi Food and Drug Authority (SFDA) regulations. It also meets the standards of the U.S. Food and Drug Administration (FDA) and European regulations. Polyethylene is known for its resistance to dissolved salts in water and many chemical substances.

Al-Kawthar Tank Factory manufactures tanks under strict quality control, in compliance with the standards and regulations of the Saudi Standards, Metrology, and Quality Organization (SASO), ensuring long-lasting durability. Al-Kawthar tanks come with a 10-year warranty.

Horizontal Tanks

Vertical Tanks

Staircase Tanks

Corridor Tanks

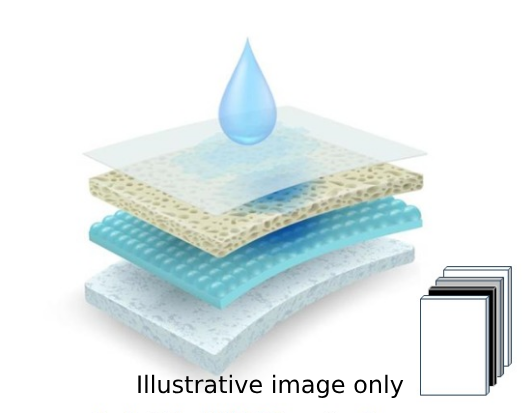

Al-Kawthar Tanks are made up of four layers, with each layer playing a crucial role in ensuring superior performance and high durability. The layers include:

Four Layers, One Piece (Seamless):

First Layer (Outer Layer): Prevents dust absorption and resists the passage of UV rays. It comes in white or beige, and can be provided in various colors upon customer request.

Made from polyethylene material produced by SABIC, approved by the Food and Drug Authority (FDA).

All connectors used are of high quality and certified.

The tank cover is tightly sealed.

Available in approved colors for the local market and export.

Specifications and Manufacturing Process

Al-Kawthar Tanks are manufactured from polyethylene material provided by SABIC, a leading Saudi company, using the Roto-Molding (Rotational Molding) technique. This process produces a one-piece, cohesive water tank with four layers designed for maximum performance:

Dust-resistant layer

Light-insulating layer to prevent algae formation

UV-resistant layer to protect the tank from harmful ultraviolet rays

Smooth interior layer in direct contact with water, preventing the accumulation of dust and debris on the tank walls

The tanks are produced in accordance with the standards set by the Saudi Standards, Metrology, and Quality Organization (SASO). They are available in sizes up to 20,000 liters and come with a 10-year warranty for durability and reliability.

Development:

To keep up with the advancements in modern tank manufacturing technologies, Al-Kawthar Tank Factory has expanded its production capabilities by introducing new production lines that utilize Blow Molding technology. This process uses high-density polyethylene from SABIC, which is safe, environmentally friendly, and highly efficient in terms of both production capacity and quality.

The adoption of blow molding technology enhances the factory's ability to produce high-quality tanks in a more cost-effective and sustainable manner.

Correct Tank Installation Position

For proper installation and to avoid damage to the tank body, polyethylene tanks should always be placed on a level surface. The manufacturer's recommendation for tank installation is to use a flat and level base or stand that makes full contact with the bottom of the tank.

Key points for proper installation:

Flat, Level Surface:

The surface where the tank is installed should be completely level to avoid uneven pressure on the tank, which could cause deformation or damage over time.

Use of Solid Base or Stand:

It is recommended to use a flat base or platform that is entirely level to ensure even weight distribution across the entire surface of the tank.

Base materials should be flat and stable, not made of scattered rods or irregular surfaces, to ensure that the weight of the tank is evenly distributed.

Even Pressure Distribution:

The base used should be constructed of smooth, level strips or a solid, continuous platform. This ensures the pressure is distributed evenly across the tank's bottom surface, preventing any localized stress that might damage the tank.

By following these recommendations, you can ensure that your polyethylene tank is installed securely, maximizing its durability and performance.